JIS A 9510 Calcium Silicate Insulation Material(JIS A 9510 No. 1-15 for Insulation Covers and Boards)

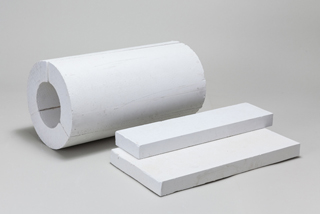

Super Feather Silica Cover /

Super Feather Silica Board

AAMNo.

- Super Feather Silica Cover:7717

- Super Feather Silica Board:7718

Super Feather Silica is mainly comprised of xonotlite crystal and reinforced fiber, meeting specifications of JIS A 9510 No. 1-15 for Insulation Covers and Boards.

Super Feather Silica’s bending and compressive strengths exceed those of both rockwool and perlite insulation materials, ensuring the reliability required for even areas most susceptive to vibration and impact.

At the same time, Super Feather Silica has less thermal conductivity than that of either rockwool or perlite insulation materials, with outstanding thermal insulation performance.

Features

- Light weight ensures easy handling.

- Extreme heat-resistance and low thermal shrinkage rate ensure minimal deterioration over time as well as ongoing stability.

- Super Feather Silica Cover : primarily used in plant piping

A pre-cut elbow cover fitting the curved pipe is also available. - Super Feather Silica Board : primarily used in heat insulation for tanks and machinery

We also offer R-boards, which reduce both man-hours and on-site industrial waste. - Water-repellent covers and boards are also available (meeting the JIS A 9510 98% water-repellent standard).

- Can be used with austenitic stainless steel

Please inquire for further details.

Usage

- Insulates boilers, turbines, and piping in power generation plants

- Insulates tanks and piping in petrochemical and oil refinery plants

- Insulates heating furnaces, equipment, and piping in other plants

Physical Properties

| Item | Unit | JIS A 9510 No. 1-15 (2016) | |

|---|---|---|---|

| Bulk Density | kg/m3 | 155 max. | |

| Bending Strength | N/cm2 | 20 min. | |

| Compressive Strength | N/cm2 | 30 min. | |

| Linear Shrinkage (1000℃ – 3hr) |

% | 2.0 max. | |

| Thermal Conductivity | 200℃ | W/(m・K) | 0.066 max. |

| 300℃ | 0.079 max. | ||

| 400℃ | 0.095 max. | ||

| 500℃ | 0.114 max. | ||

| 600℃ | 0.137 max. | ||

| JIS A 9501 Reference Formula |

0.0407+0.000128・θ (200≦θ≦300) θ: temperature [℃] |

||

| Maximum Service Temperature* | ℃ | 1000 | |

- ※The maximum service temperature is defined the temperature at which the shrinkage rate is 2% or less and cracking or wrapping does not occur.

For further details, please refer to JIS A 9501 Standard Practice for Thermal Insulation Works.

Dimensions

- Covers

Thickness [mm] Designated aperture [A] Length [mm] 30、40、50、65、75 15 to 850 610 - *Further details concerning cover dimensions may be found in the Entry Table.

- Boards

Thickness [mm] Width [mm] Length [mm] 30、40、50、65、75、100 150、303 610 - *Please inquire for further details concerning R-boards.

Other

- Please refer to the Safety Data Sheet (SDS) for details concerning handling and/or safety.

Inquiries

Online Inquiries

Direct Inquiries

A&A Material Corporation

Industrial Products Sales Department

TEL:+81-3-3458-9375