Carrier Roll for High Temperature Rolling

Disc Roll

AAMNo.

- 2055,2057,2055-3S,2055-HA

Disc Rolls are the punched discs from millboards, inserted in shafts and laminated, and then fastened and polished into conveyor rollers for high heat-treatment materials.

Millboards are made primarily of heat-resistant inorganic fiber and they are molded paper products manufactured with heat-resistant fillers and organic binders.

Features

- Demonstrates ongoing stability with stainless steel veneer lines at 1150-1200℃ for prolonged periods

- Exhibits moderate hardness and superior adiabaticity, with a firmness yielding outstanding abrasion resistance

- Minimal linear shrinkage enables stabilized conveyor functions without deformity over the long term.

- High adiabaticity preserves roll surface temperature, suppressing cooling energy loss from the shaft and contributing to energy conservation.

Usage

- Conveyor roller for high heat treatment material, for use with stainless steel veneer continuous annealing furnaces

- Conveyor roller for high heat treatment material, for use with a wide range of plate glass, slow-cooling furnaces

Physical Properties

(Physical Properties of Millboards for Disc Rolls)

| Characteristics | Unit | AAMNo. 2055 |

AAMNo. 2057 |

AAMNo. 2055-3S |

AAMNo. 2055HA |

||

|---|---|---|---|---|---|---|---|

| All-purpose Type | Low Scale-adhesion Type | Low-abrasion Type | Ultra Heat-resistant Type | ||||

| Bulk Density | g/cm3 | 0.8 | 0.8 | 0.9 | 0.8 | ||

| Thermal Shrinkage | 1100℃ Post-treatment |

Longitudinal | % | 3 | 3 | 2 | 1 |

| Lateral | 4 | 3 | 3 | 1 | |||

| 1200℃ Post-treatment |

Longitudinal | 4 | 3 | 4 | 1 | ||

| Lateral | 5 | 4 | 5 | 2 | |||

| Tensile Strength | 100℃ Post-treatment |

Longitudinal | MPa | 3 | 4 | 4 | 3 |

| Lateral | 2 | 3 | 3 | 2 | |||

| 400℃ Post-treatment |

Longitudinal | 0.2~0.4 | |||||

| Lateral | 0.2~0.3 | ||||||

| Chemical Composition | SiO2 | wt% | 35 | 32 | 32 | 32 | |

| Al2O3 | 39 | 45 | 42 | 42 | |||

| CaO | 3 | 2 | 4 | 4 | |||

| MgO | 9 | 8 | 8 | 8 | |||

| Other | 1 | 1 | 1 | 1 | |||

| Ignition Loss | 13 | 12 | 13 | 13 | |||

- *The values in the technical data given above are typical test results and are not guaranteed.

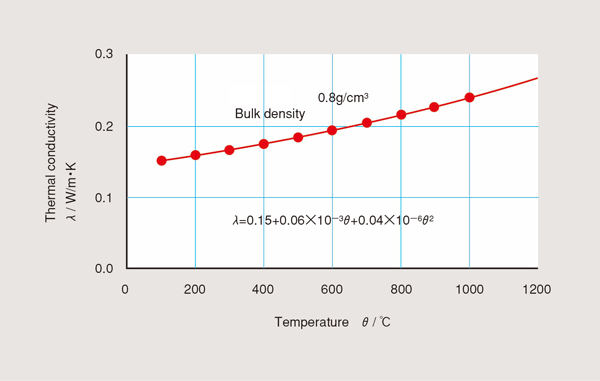

Thermal Conductivity

Handling Precautions

- 1)Do not allow the Disc Rolls to absorb moisture.

As the rolls absorb moisture easily, they should be stored in a dry location. They should not be exposed to rainwater and should not be kept in a humid location. - 2)Rapid heating and cooling pre-/post-usage should be avoided.

The roll should be installed in the furnace at 600℃ or less, and the prescribed temperature should be achieved over the course of 2-3 hours.

Cooling should occur over a period of 3-4 hours until the furnace reaches a temperature of less than 500℃. Cooling should not occur rapidly.

Note : Rapid heating/cooling can lead to cracks in the roll surface, impacting future use. - 3)When used at a high temperature, the shaft (metal core) should be cooled.

Note : Exact temperatures vary according to the shaft material and operating conditions, but approximately 700℃ is the approximate target. When cooling with water, coolant flow should be ample. - 4)Mechanical shock should be avoided.

Disc Roll surface is polished, and requires careful handling. In particular, note that after heating, Disc Roll loses some firmness. - 5)Tools should not be suspended from the roll surface.

Wires or slings suspended from the roll surface may cause damage. - 6)A&AM cannot be held responsible for any failure caused by nonconformance to the above cautions, and/or any actions taken to obstruct proper performance of Disc Rolls.

- 7)Kindly refer to the Safety Data Sheet (SDS) before use.

Other

- Kindly refer to the Disc Material (millboard) Safety Data Sheet for further information on handling precautions or safety issues.

Inquiries

Online Inquiries

Direct Inquiries

A&A Material Corporation

Industrial Products Sales Department

TEL:+81-3-3458-9375